Flow-Control 3/K

automatic fuel oil de-aerator

- trouble-free operation due to automatic de-aeration

- Dual float safety system keeps oil foam from escaping

- increased fuel oil filter service life - the amount of oil drawn from the tank corresponds exactly to the oil actually burnt

- the suction line can usually have a smaller cross section

- PROOFED BARRIER if installed with vent hose

- materials resistant to biofuel and biodiesel mixtures with max. 30 % FAME

- green fuels ready: suitable for use at tank facilities filed with the new paraffinic fuels HVO or GTL

- watertight up to 10 m water column - ideal for use in flood hazard areas

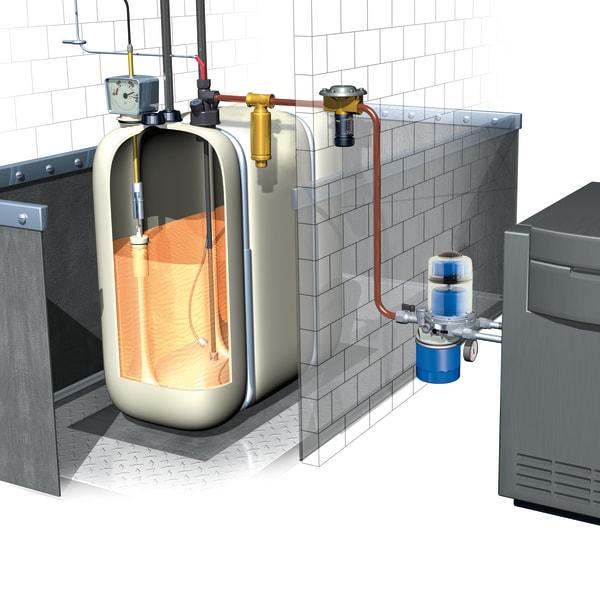

For single-line systems with return line in oil-fired systems for continuous de-aeration. Suitable for fuel oil EL (DIN 51603-1), diesel fuel (EN 590), liquid fuels as per DIN SPEC 51603-6 and DIN/TS 51603-8 as well as biofuel and biodiesel with a maximum of 30 % FAME (EN 14214). This product is therefore ideal for all ecologically upgraded fuel oil consuming systems that use the new paraffinic fuels HVO or GTL as an admixture or 100 %. Also for use in flood hazard areas and flood risk areas.

The risk of a leak in the return line going unnoticed is removed with Flow-Control. It is no longer necessary to regularly check the return line for leaks.

Automatic fuel oil de-aerator consisting of a diecast zinc housing with female G¼ connection thread at the tank end and male G⅜ connection threads with 60° cone at the burner end for connection of the burner hoses. Plastic or metal de-aerator hood. Flow-Control 3/K features two separate float chambers. The lower float chamber contains the operating float; the upper float chamber contains the safety float. The upper float chamber keeps oil foam from escaping via the vent opening (e.g. during commissioning/filter exchange) and indicates malfunctions of the vent valve. An oil hose with ball-shaped sealing for 60° cone and a G⅜ union nut is supplied for connection to the fuel oil filter. Watertight up to 10 m water column. All Flow-Control versions are TÜV-tested.

Flow-Control 3/K (G¼) with connections G¼ female thread at burner end instead of G⅜ male thread.

- connection burner end

- part no. 69930: G⅜ male with 60° cone for burner hoses

- Connection tank

- G¼ female

- Nozzle capacity

- max. 100 l/h

- Return flow

- max. 120 l/h

- Separating capacity air/gas

- ca. 4 l/h

- Mounting position

- Float housing vertical to the top

- Operating temperature range

- Medium:

- max. 60 °C

- Ambient:

- max. 60 °C

- Operating overpressure

- max. 0.7 bar

- (corresponds to static oil column of approx. 8 m)

- Test pressure

- 6 bar

- Dimensions (W x H x D)

- 95 x 147 x 95 mm

- Material

- Housing:

- Zinc die cast

- De-aerator hood:

- Plastic

- Test

- TÜV-tested (S 556 2021 S1)

- approval

- Conformity certificate (ÜHP) as per EN 12514