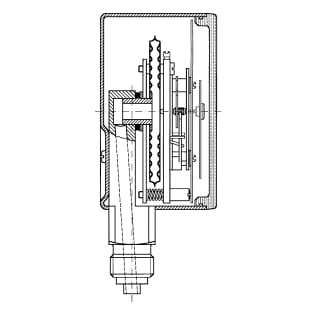

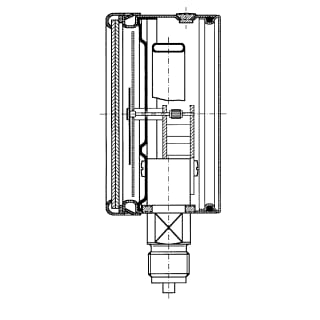

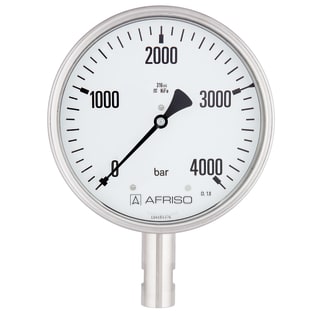

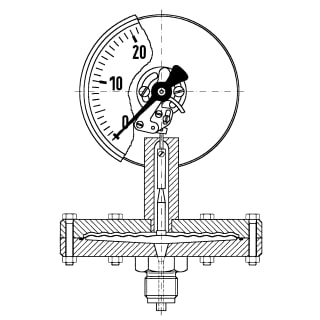

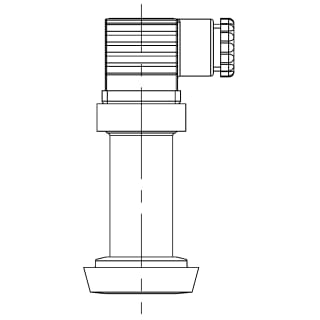

Specific production processes

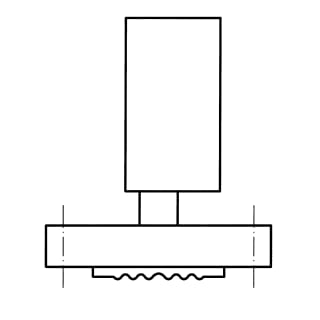

AFRISO components and system solutions are adapted to suit specific production processes and comply with the pertinent hygienic regulations and recommendations to meet stringent requirements. Our robust measuring devices deliver perfect measuring results and reliably monitor and control simple to highly complex processes. Sophisticated kit systems and innovative ideas such as the seal-free design of diaphragm seals, pressure transmitters and thermometers help in the continuous optimisation of production facilities.